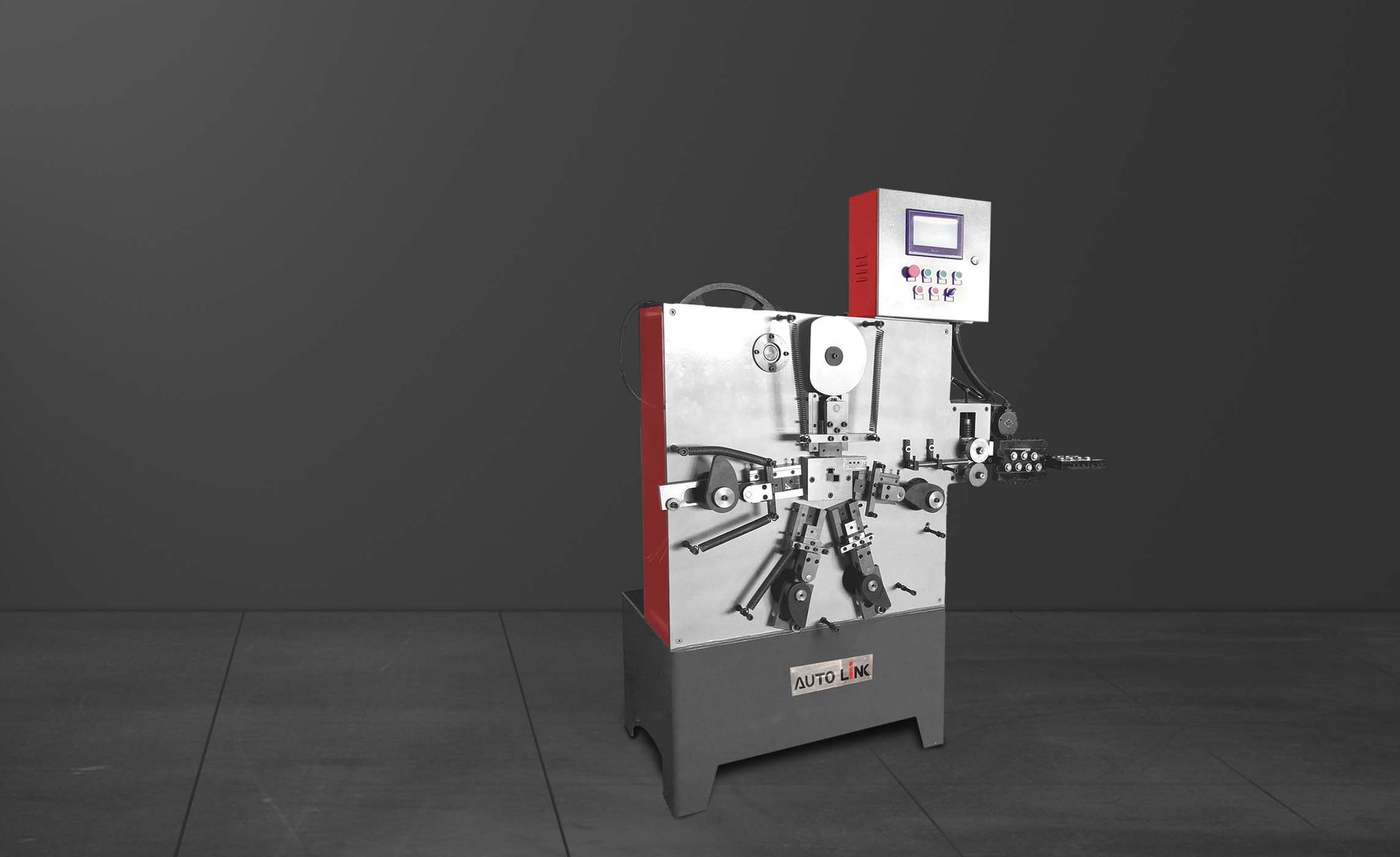

Buckle Making Machine

Product Application & case

Product Details

| Model | AL-SB 3.5 |

| Size | 1.5-3.5mm |

| Strap Size | 12/16mm |

| Feeding Length | 300mm |

| Production Rate | 50-60/min |

| Motor Power | 2.2kw |

| Dimension(L*W*H) | 1700*600*1680 |

| Weight | 750KG |

AL-SB3.5

| Model | AL-SB 3.5 |

| Size | 1.5-3.5mm |

| Strap Size | 12/16mm |

| Feeding Length | 300mm |

| Production Rate | 50-60/min |

| Motor Power | 2.2kw |

| Dimension(L*W*H) | 1700*600*1680 |

| Weight | 750KG |

The CNC buckle-making machine uses CNC technology to control the cutting, bending, and shaping of metal sheets into the desired buckle shape. The machine typically consists of a cutting station, a bending station, and a shaping station.

The cutting station uses a high-speed cutting tool to cut the metal sheets into the desired shape. The bending station uses a series of rollers and dies to bend the metal into the desired buckle shape. The shaping station uses a series of punches and dies to shape and finish the buckle. The CNC buckle-making machine is a highly efficient and precise tool that helps to achieve consistent and high-quality buckle production.

This machine is widely used in the leather goods industry and is suitable for producing a wide range of buckle designs and sizes. The use of CNC technology in buckle making helps to achieve consistent buckle quality, reduced production time, and improved production efficiency.

FEATURES OF OUR BUCKLE-MAKING MACHINE

- Automation: The machine is fully automated, reducing the need for manual intervention and increasing efficiency.

- High speed: Industrial CNC buckle-making machines are capable of performing cutting and shaping operations at high speed, reducing production time and increasing efficiency.

- Precision: The machine uses CNC technology to ensure high-precision cutting and shaping, which results in buckles that meet exact specifications.

- Versatility: Industrial CNC buckle-making machines can produce a wide range of buckle designs, including simple buckles, complex buckles, and custom buckles.

- Durability and maintenance: The machine is designed for low maintenance, with easy-to-access components and robust construction that is built to last.

APPLICATIONS OF OUR MACHINE

- Automotive: Industrial CNC buckle-making machines are used to produce buckles for seat belts, airbags, and other safety systems in the automotive industry.

- Military and law enforcement: The machines are used to manufacture high-quality buckles for military and law enforcement equipment, including holsters, vests, and belts.

- Consumer goods: Industrial CNC buckle-making machines are used to produce buckles for a wide range of consumer goods, including backpacks, luggage, and camping gear Industrial equipment: The machines are used to produce buckles for industrial equipment, such as safety harnesses, cargo straps, and load-securing systems.