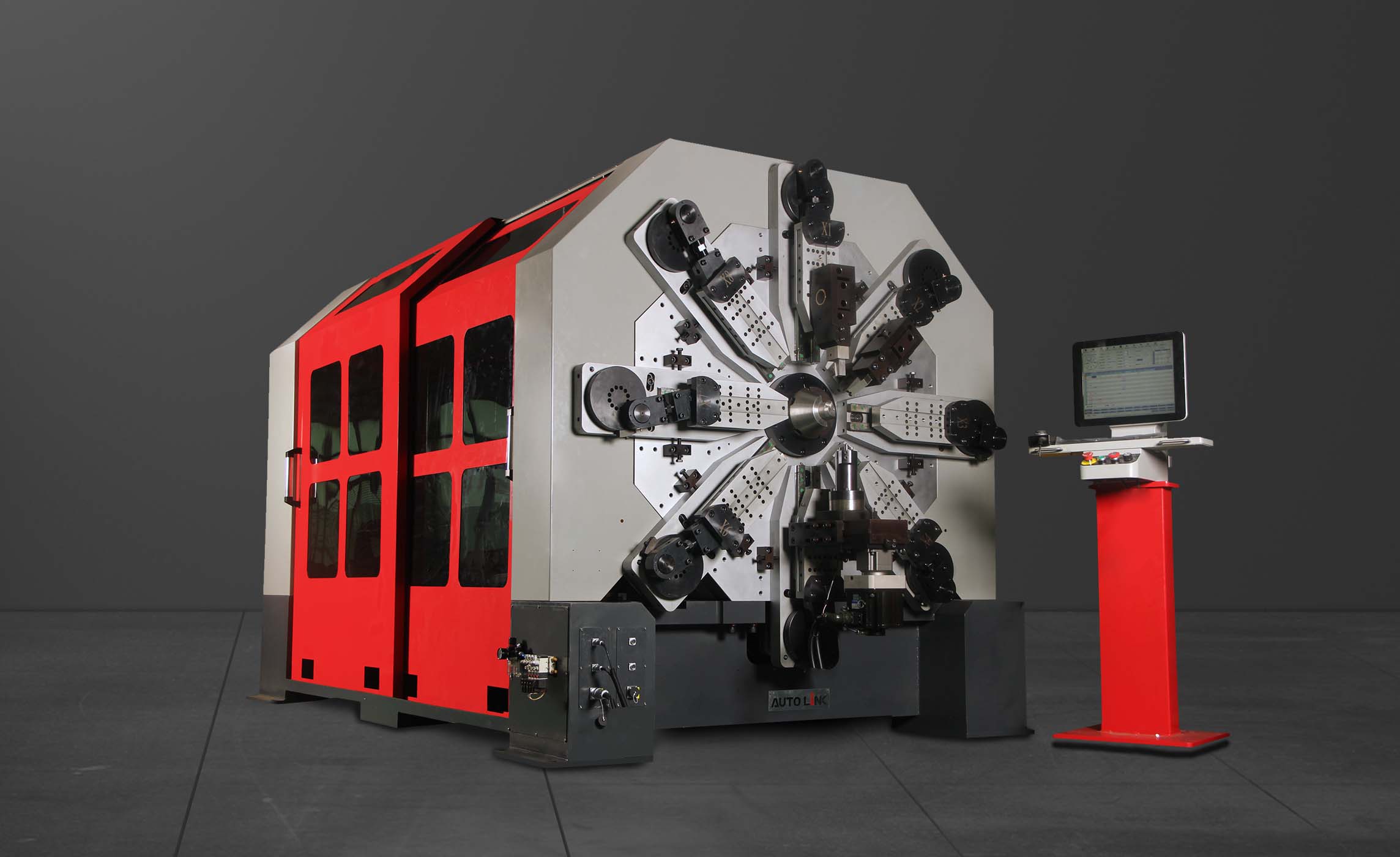

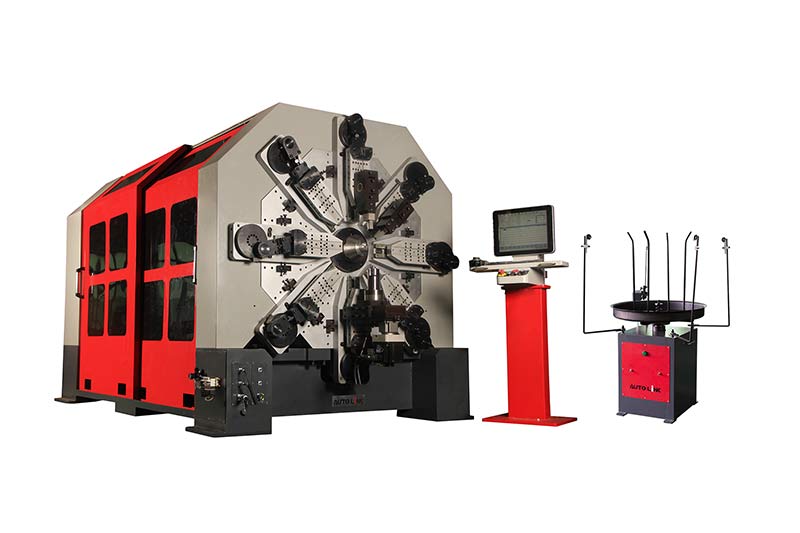

12/14 Axis CNC Wire Forming Machine

Application : 0.5-8.0mm Wire Diameter

Product Application & case

Product Details

| Model | WF-1225R |

| Wire Diameter | 0.5-2.5mm |

| Axis | 12-14 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01mm |

| Max.Wire Feed Speed | 100000 mm/min |

| Slide Axis(With Brake) | 8*0.75KW |

| Quill Rotary Axis | 1*0.4KW |

| Wire Rotary Axis | 1*2.0KW |

| Wire Feeding Axis | 1*2.7KW |

| Spinner Axis | 0.4KW |

| Free Arm Axis(Optional) | 0.4KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension(M) | 1.7*1.5*1.7 |

| Weight | 1500kg |

| Model | WF-1245R |

| Wire Diameter | 1.0-4.5mm |

| Axis | 12-14 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01 mm |

| Max.Wire Feed Speed | 80000 mm/min |

| Slide Axis(Optional) | 8*2.0KW |

| Quill Rotary Axis | 1*1.0KW |

| Wire Rotary Axis | 1*2.7KW |

| Wire Feeding Axis | 1*7.5KW |

| Spinner Axis | 1.0KW |

| Free Arm Axis(Optional) | 1.0KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension(M) | 2.2*2.0*2.1 |

| Weight | 3000kg |

| Model | WF-1265R |

| Wire Diameter | 2.5-6.5mm |

| Axis | 12-14 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01mm |

| Max.Wire Feed Speed | 30000 mm/min |

| Servo Cutter | 2kw |

| Slide Axis(Optional) | 8*4.5KW |

| Quill Rotary Axis | 1*1.2KW |

| Wire Rotary Axis | 1*4.5KW |

| Wire Feeding Axis | 1*15KW |

| Spinner Axis | 2.7KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension | 3.6*2.1*2.1 |

| Weight | 6500Kg |

WF-1225R

| Model | WF-1225R |

| Wire Diameter | 0.5-2.5mm |

| Axis | 12-14 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01mm |

| Max.Wire Feed Speed | 100000 mm/min |

| Slide Axis(With Brake) | 8*0.75KW |

| Quill Rotary Axis | 1*0.4KW |

| Wire Rotary Axis | 1*2.0KW |

| Wire Feeding Axis | 1*2.7KW |

| Spinner Axis | 0.4KW |

| Free Arm Axis(Optional) | 0.4KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension(M) | 1.7*1.5*1.7 |

| Weight | 1500kg |

WF-1245R

| Model | WF-1245R |

| Wire Diameter | 1.0-4.5mm |

| Axis | 12-14 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01 mm |

| Max.Wire Feed Speed | 80000 mm/min |

| Slide Axis(Optional) | 8*2.0KW |

| Quill Rotary Axis | 1*1.0KW |

| Wire Rotary Axis | 1*2.7KW |

| Wire Feeding Axis | 1*7.5KW |

| Spinner Axis | 1.0KW |

| Free Arm Axis(Optional) | 1.0KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension(M) | 2.2*2.0*2.1 |

| Weight | 3000kg |

WF-1265R

| Model | WF-1265R |

| Wire Diameter | 2.5-6.5mm |

| Axis | 12-14 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01mm |

| Max.Wire Feed Speed | 30000 mm/min |

| Servo Cutter | 2kw |

| Slide Axis(Optional) | 8*4.5KW |

| Quill Rotary Axis | 1*1.2KW |

| Wire Rotary Axis | 1*4.5KW |

| Wire Feeding Axis | 1*15KW |

| Spinner Axis | 2.7KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension | 3.6*2.1*2.1 |

| Weight | 6500Kg |

The camless 12-axis CNC wire-forming machine is a versatile solution for a range of applications. The rotary capability of the machine enables the use of multiple tools at once, resulting in improved efficiency. This machine streamlines the design and production of both simple and complex wire forms, driving a drastic increase in production rate. Its exceptional performance in spring forming is especially noteworthy, as it can effortlessly produce intricate wire bends and shapes.

Laiyue Metals Works Pvt. Ltd., specializes in producing complex spring shapes, such as compression, extension, and tension springs, all crafted to meet customer specifications.

The CNC Wire Forming Machine camless design with 8 motors and 8 arms, making it more efficient than other models. The machine takes user input and the wire is loaded into a decoiler unit with a capacity ranging from 150kg to 1000kg. With 12/14 axis capabilities, this automatic machine is suitable for a wide range of applications. The wire rotary model enhances production speed, reducing overall production time. Bending, holding, punching, softening, or quilling processes are customized to meet customer needs and the CNC program is adjusted to fit industrial requirements. For simple wire bending or forming, the machine can be configured with fewer axes.

Input Materials: Stainless Steel, Aluminum, Brass, Bronze, Carbon Steel, Cold-Rolled Steel, Copper, Nickel, Titanium, etc. Then the input wire ranges from 0.5mm to 6.5mm in diameter.

Available Models: WF-1225R, WF-1245R & WF-1265R

Features of 12/14 Axis CNC Wire Forming Machines:

- Versatility: With 12 axes of control, the machine can handle a wide range of wire-forming tasks, including bending, holding, punching, softening, and quilling.

- Customization: The machine is equipped with software that allows for customization of the wire-forming process to meet the specific needs of each customer.

- Cost savings: The machine's ability to automate many tasks and produce high-quality wire forms can lead to cost savings in the long run.

- High efficiency: The machine's design, with multiple motors and arms, allows it to operate with greater speed and accuracy compared to other wire-forming machines.

- Improved output quality: The machine's advanced capabilities allow it to produce wire forms of a higher quality than manual or less sophisticated machines.

Industrial and Commercial Applications:

Now, Laiyue Metal Works is also widely spreading its business through Indiamart and Made in China. Therefore, the CNC machine effectively produces the output with respect to industrial needs.

- Springs: Variety of springs, including compression, tension, torsion springs, etc.

- Wire baskets: Material handling, storage, transportation, etc.

- Hinges: Doors, cabinets, electrical enclosures, etc.

- Racks and shelving: Retail displays, storage, material handling, etc.

- Hooks and hangers: Material handling, Retail displays, storage, etc.

- Medical devices: intravenous poles, surgical instruments, Adjustable cots, etc.